Welcome to our ISO 9001:2015 consulting service! With experience and expertise in the field of ISO 9001:2015 consulting, we are proud to provide high-quality consulting services to help your business achieve ISO 9001:2015 international standards.

Our consulting services are designed to help businesses improve operational efficiency, enhance competitiveness and ensure the quality of products and services. We have a team of experienced consultants, ready to assist you in the process of bringing your business to international standards.

ISO 9001 is an international standard for quality management systems (QMS). To be certified according to the ISO 9001 standard, a company must comply with the requirements set out in the ISO 9001 Standard. However, understanding and applying this standard on its own is a challenge for many businesses because many Human resources do not clearly understand standard requirements, have no implementation experience…

Therefore, instead of learning and implementing it themselves, businesses have sought the help of professional consulting companies – where there are experienced ISO 9001 consultants to help them build and deploy. quality management system according to ISO 9001:2015 standards effectively – accurately – saving time.

If your business is also facing the same problem, please refer to Dqs Center’s ISO 9001 consulting service!

Which businesses should apply ISO 9001?

A large number of businesses in many countries around the world apply ISO 9001 standards to their systems. It allows companies to maintain high standards of quality assurance. In addition, it is also recognized as an important indicator of a company’s commitment to running its business effectively.

ISO 9001 is the standard for quality management systems. Therefore, any business with a quality management system can develop and apply ISO 9001, including manufacturing and service industries.

• It doesn’t matter what the size of the organization/business is: a few people to more than tens of thousands of people.

• It doesn’t matter the industry – it could be a restaurant, a consulting company, a manufacturing company, a government agency, etc. There are different standards under ISO 9001 for specific industries. Some specific industries that businesses receive many benefits from ISO 9001 are: Construction, Engineering, Manufacturing, Technology, Hotel Services, Health Care

Benefits when applying ISO 9001:2015

Enhance reputation and business image

The ISO 9001 standard has become the basis for creating a worldwide quality management system. Achieving ISO 9001 certification can be a powerful marketing tool, enhancing a business’s image and reputation.

Improve customer satisfaction

Improving customer satisfaction by planning and striving to meet customer requirements is one of the foundations of ISO 9001. By improving customer satisfaction, businesses can keep retain many loyal customers and bring in more revenue.

Better process integration

Better process integration reduces errors, drives efficiency and saves costs

Continuous improvement

Continuous improvement is applied to improve an organization’s processes and outputs, delivering ongoing benefits to the business.

Employee engagement

Employees who participate in improving the processes in which they work are happier and more engaged employees. Engaged employees are more productive and will help the company grow, especially when they understand how the quality of the process depends on them.

Our ISO 9001:2015 consulting services include:

– Train employees on ISO 9001:2015 and process improvement methods.

Design and implement a quality management system according to ISO 9001:2015

– Check and evaluate the effectiveness of the current quality management system.

– Support in the process of building registration documents for ISO 9001:2015 certification.

– Provide support for businesses in the process of monitoring and updating the quality management system according to ISO 9001:2015.

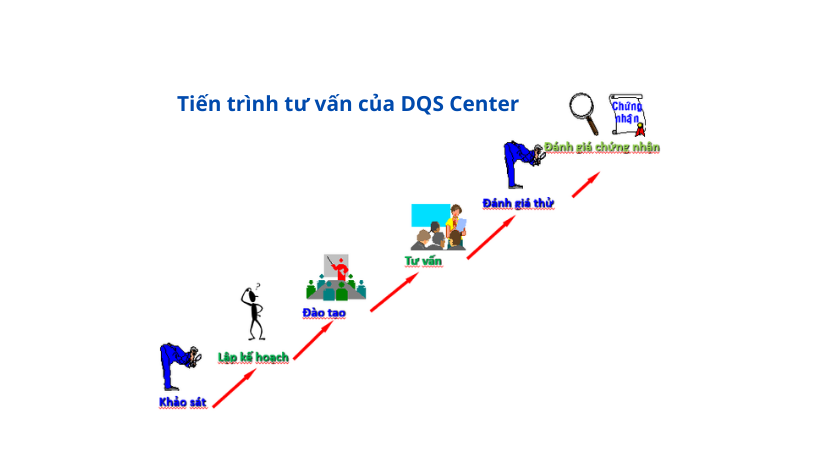

How does our consulting service support you about iso 9001:2015?

HOW CAN WE ASSIST YOU WITH ISO 9001: 2015

1. Gap Assessment

We offer this service to organizations that have existing documents including policies, procedures, manuals, forms, handbooks, etc., and would like to check if the existing documents meet the requirements of the desired standards and what they need to do to certify the system.

2. System Development

We offer this service to organizations that do not have any existing system (documents) including policies, procedures, manuals, forms, handbooks, etc. or the gap assessment shows that their existing system needs to improve to meet the requirements of the desired standard.

3. Implementation

A Management system should be documented and implemented to meet the requirements of the desired standards. We will supervise and guide our clients during the Implementation of the management while they follow the policies and procedures and use the forms.

4. Internal Audit

An annual internal audit is required to get certified and maintain the ISO certificates. We offer this service to organizations that do not have the internal resources to conduct internal audits or would like to have a new pair of eyes to detect opportunities for improvement

5. Attending External Audit

Dealing with the external auditor might be quite stressful and challenging for organizations, particularly those willing to certify their system for the first time. We will attend the external audit and assist them as a facilitator for a better and smoother experience.

6. Ongoing Maintenance

Once the organizations achieve their certificate, they will face a new challenge for maintaining what they have achieved as every year the certification body comes back for a surveillance audit. We offer this service to draw their attention to what they might miss in the routines.

Time for work Development System according to item 2, from 2 to 7 months, depending on the organization’s production and business situation

ISO 9001: 2015 TRAINING & CONSULTING PLAN

|

Sq. |

Items of ISO project

|

In charge |

Progress with milestone (month/ week) |

Total Man-days |

|||||||||||||||||||||||

1st month |

2nd month |

3rd month |

4th month |

5th month |

6th month |

||||||||||||||||||||||

|

1 |

2 |

3 |

4 |

1 |

2 |

3 |

4 |

1 |

2 |

3 |

4 |

1 |

2 |

3 |

4 |

1 |

2 |

3 |

4 |

1 |

2 |

3 |

4 |

||||

|

1 |

Factory tour & general documents & records survey |

Consultant & ISO team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

2 |

ISO 9001 awareness & interpretation training |

Consultant & ISO team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

3 |

Writing documents assignment for each of the Depts |

ISO team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

4 |

Writing/ modification the procedures/ documents |

Consultant & ISO team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

5 |

Issue documents |

ISO team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– |

|

6 |

Training general requirements to ISO team |

Consultant & ISO team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

7 |

ISO 9001 internal auditor training |

Consultant & ISO team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

8 |

Internal audit |

Consultant & ISO team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

9 |

Management review |

BOD & ISO team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– |

|

10 |

Corrective action after internal audit |

Consultant & ISO team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

11 |

Pre-audit by consultant |

Consultant & ISO team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

12 |

Certificating audit – 1st stage audit (*) |

ISO team & auditors team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– |

|

13 |

Corrective action |

Consultant & ISO team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– |

|

14 |

Certificating audit – 2nd stage audit (**) |

ISO team & auditors team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– |

|

15 |

Total man-days |

|

|

|

|

|

|

|

17 |

||||||||||||||||||

Notes: Certification audit is carried out by the independent Certification Body (Ex: SGS, TUV, URS…)

(*) & (**) Certification Body will make the certification audit plan with man-days properly.

LIST OF DOCUMENTS NEED TO BE WRITTEN ACCORDING TO ISO 9001: 2015

|

Sq.

|

Document’s name

|

ISO 9001 Clause

|

|

1

|

Quality policy |

5.2

|

|

2

|

Quality objectives for each of the departments |

6.2

|

|

3

|

Quality manual (if any) |

–

|

|

4

|

Risks assessment and opportunity procedure |

6.1

|

|

5

|

Provision of human resources procedure |

7.1.2

|

|

6

|

IT instrument management procedure |

7.1.3

|

|

7

|

Maintenance and repairs production instruments procedure |

7.1.3

|

|

8

|

Control / calibration of measuring instrument procedure |

7.1.5

|

|

9

|

Management of knowledge procedure |

7.1.6

|

|

10

|

Training procedure |

7.2 & 7.3

|

|

11

|

Control of documents & data procedure |

7.5

|

|

12

|

Control of records procedure |

7.5

|

|

13

|

Control plan (for each type of product) |

8.1

|

|

14

|

Contract/ PO review procedure |

8.2

|

|

15

|

Design procedure (if your organization has design process) |

8.3

|

|

16

|

Management of suppliers evaluation procedure |

8.4.3

|

|

17

|

Purchase procedure |

8.4

|

|

18

|

Checking material procedure |

8.4

|

|

19

|

Outsource management procedure (if any) |

8.4

|

|

20

|

Control of manufacturing procedures |

8.5.1

|

|

21

|

Control of service provision procedure |

8.5.1

|

|

22

|

Import – Export procedure |

8.5.1

|

|

23

|

Input – output management procedure (warehouse) |

8.5.4

|

|

24

|

Customer complaints procedure |

8.5.5

|

|

25

|

Control of changes procedure |

8.5.6

|

|

26

|

In-process & final check procedures |

8.6

|

|

27

|

Control of non-conforming product procedure |

8.7

|

|

28

|

Customer survey procedure |

9.1.2

|

|

29

|

Analysis of data procedure |

9.1.3

|

|

30

|

Internal audit procedure |

9.2

|

|

31

|

Management review procedure |

9.3

|

|

32

|

Corrective action procedure |

10.2

|

|

33

|

Improvement procedure |

10.3

|

|

34

|

Job descriptions (JD) |

5.3

|

|

35

|

Work instructions |

—

|

Tiếng Việt

Tiếng Việt