Consulting IATF 16949:2016 – Improve product quality for your business, Are you looking for a reliable partner to improve the product quality of your automotive and auto parts business? Come to Dqs Center – a reputable and quality IATF 16949:2016 consulting unit.

IATF 16949:2016 is an international standard applied to the quality management systems of automobile and auto component manufacturers. This standard sets forth strict requirements for quality, safety, and environmental protection, in order to ensure the full satisfaction of product standards of the automotive industry. In preparation for the IATF 16949:2016 version, comments were sought from certification bodies, auditors, suppliers, and OEMs to create the first version and replacement of the IATF 16949:2016 standard. replaces the ISO/TS 16949: 2009 standard. In addition, the World Automobile Association IATF maintains close cooperation with the International Organization for Standardization ISO by maintaining its position as an intergovernmental committee. Contact ensures alignment with ISO 9001:2015.

The IATF 16949:2016 standard is designed to be used in addition to the requirements of ISO 9001:2015. It includes additional requirements specific to the automotive industry, rather than as a stand-alone ISO 9001. This standard specifies the requirements for establishing, implementing, maintaining, and continuously improving a QMS for any organization regardless of size in the automotive industry. IATF 16949:2016 sets out the requirements to assist organizations in achieving best practices when carrying out the design, development, production, installation, or maintenance of products. automobile products.

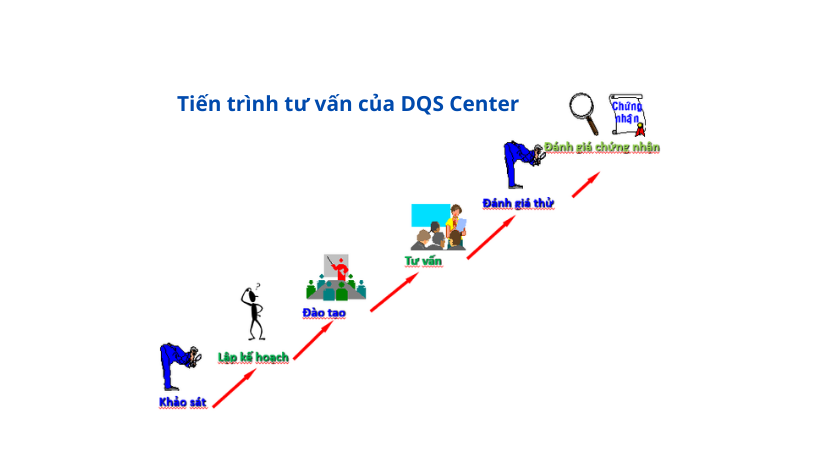

With a team of experienced professionals and in-depth knowledge of IATF 16949:2016, we provide optimal consulting services to help your business meet the requirements of this standard. We provide customized and flexible consulting solutions, tailored to the unique needs and characteristics of each business. How does our consulting service help you with IATF 16949:2016?

HOW CAN WE ASSIST YOU IATF 16949: 2016

1. Gap Assessment

We offer this service to organizations that have existing documents including policies, procedures, manuals, forms, handbooks, etc. and would like to check if the existing documents meet the requirements of the desired standards and what they need to do to certify the system.

2.System Development

We offer this service to organizations that do not have any existing system (documents) including policies, procedures, manuals, forms, handbooks, etc. or the gap assessment shows that their existing system needs to improve to meet the requirements of the desired standard.

3.Implementation

A Management system should be documented and implemented to meet the requirements of the desired standards. We will supervise and guide our clients during the Implementation of the management while they follow the policies and procedures and use the forms.

4.Internal Audit

An annual internal audit is required to get certified and maintain the IATF certificates. We offer this service to organizations that do not have the internal resources to conduct the internal audits or would like to have a new pair of eyes to detect the opportunities for improvement

5. Attending External Audit

Dealing with the external auditor might be quite stressful and challenging for the organizations, particularly for the ones that are willing to certify their system for the first time. We will attend the external audit and assist them as a facilitator for a better and smoother experience.

6. Ongoing Maintenance

Once the organizations achieve their certificate, they will face a new challenge for maintaining what they have achieved as every year the certification body comes back for a surveillance audit. We offer this service to draw their attention to what they might miss in the routines. View more IATF 16949

IATF 16949: 2016 TRAINING & CONSULTING PLAN

|

Sq. |

Items of IATF project |

In charge |

Progress with milestone (month/ week) |

Total Man-days |

|||||||||||||||||||||||||||||||||||||||||||||||

1st month |

2nd month |

3rd month |

4th month |

5th month |

6th month |

7th month |

8th month |

9th month |

10th month |

11th month |

12th month |

||||||||||||||||||||||||||||||||||||||||

|

1 |

2 |

3 |

4 |

1 |

2 |

3 |

4 |

1 |

2 |

3 |

4 |

1 |

2 |

3 |

4 |

1 |

2 |

3 |

4 |

1 |

2 |

3 |

4 |

1 |

2 |

3 |

4 |

1 |

2 |

3 |

4 |

1 |

2 |

3 |

4 |

1 |

2 |

3 |

4 |

1 |

2 |

3 |

4 |

1 |

2 |

3 |

4 |

||||

|

1 |

Factory tour & general documents & records survey |

Consultant & IATF Team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

2 |

IATF 16949 awareness & interpretation training |

Consultant & IATF Team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

3 |

Writing documents assignment for each of the Depts |

IATF Team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

4 |

Writing/ modification the procedures/ documents |

Consultant & IATF Team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

5 |

Issue documents |

IATF Team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– |

|

6 |

Core tools training: FMEA, MSA, SPC, PPAP, APQP |

Consultant & IATF Team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

7 |

Training general requirements to IATF team |

Consultant & IATF Team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

8 |

Apply the IATF 16949 documents system |

Consultant & IATF Team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

9 |

IATF 16949 internal auditor training |

Consultant & IATF Team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

10 |

Internal audit |

Consultant & IATF Team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

11 |

Management review |

BOD & IATF Team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– |

|

12 |

Corrective action after internal audit |

Consultant & IATF Team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

13 |

Pre-audit by consultant |

Consultant & IATF Team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

14 |

Certificating audit – 1st stage audit (*) |

IATF team & auditors team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– |

|

15 |

Corrective action |

Consultant & IATF Team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

16 |

Certificating audit – 2nd stage audit (**) |

IATF team & auditors team |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– |

|

17 |

Total man-days |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

34 |

Notes: Certification audit is carried out by the independent Certification Body (Ex: SGS, TUV…)

(*) & (**) Certification Body will make the certification audit plan with man-days properly.

LIST OF DOCUMENTS NEED TO BE WRITTEN ACCORDING TO IATF 16949: 2016

|

Sq.

|

Document’s name

|

IATF 16949 Clause

|

|

1

|

IATF Quality policy |

5.2

|

|

2

|

Quality objective |

6.2

|

|

3

|

IATF Manual |

7.5.1.1

|

|

4

|

Context of the organization |

4.1

|

|

5

|

The needs and expectations of interested parties |

4.2

|

|

6

|

The management of product safety procedure |

4.4.1.2

|

|

7

|

Corporate responsibility policy |

5.1.1.1

|

|

8

|

Process owners list |

5.1.1.3

|

|

9

|

Job descriptions |

5.3

|

|

10

|

Risks & opportunities addressing procedure |

6.1.2.1

|

|

11

|

Preventive action procedure |

6.1.2.2

|

|

12

|

Emergency response procedure |

6.1.2.3

|

|

13

|

Provision of human resources procedure |

7.1.2

|

|

14

|

Equipment maintenance procedure |

7.1.3

|

|

15

|

Equipment repair procedure |

7.1.3

|

|

16

|

Equipment, molds, fixtures, tools management & manufacture procedure |

7.1.3

8.5.1.6

|

|

17

|

Management, maintenance & repairing of molds, fixtures, tools procedure |

7.1.3

|

|

18

|

Plant, facility, and equipment planning procedure |

7.1.3.1

|

|

19

|

Control of work environment procedure (5S) |

7.1.4

|

|

20

|

Measurement instruments & tools calibration management procedure |

7.1.5

|

|

21

|

Control of measurement system analysis procedure (MSA) |

7.1.5.1.1

|

|

22

|

Internal & external laboratory management procedure |

7.1.5.3

|

|

23

|

Knowledge management procedure |

7.1.6

|

|

24

|

Awareness training & assessment skill of employees procedure |

7.2 & 7.3

|

|

25

|

OJT training & assessment skill of employees procedure |

7.2.2

|

|

26

|

Competence determination & verification procedure for internal auditor, supplier auditor, visible inspection and special processes |

7.2

|

|

27

|

Employees motivation procedure |

7.3.2

|

|

28

|

Control of documents procedure |

7.5

|

|

29

|

Control of records procedure |

7.5

|

|

30

|

Engineering standards/specifications control procedure |

7.5.3.2.2

|

|

31

|

Customer complaints solving procedure |

8.2.1

|

|

32

|

Sale contract reviewing procedure |

8.2.

|

|

33

|

APQP procedure |

8.3

|

|

34

|

Molds, fixtures & tools design procedure |

8.3

|

|

35

|

PPAP procedure |

8.3

|

|

36

|

FMEA procedure |

8.3

|

|

37

|

Design change control procedure |

8.3

|

|

38

|

SPC procedure |

8.3

|

|

39

|

Special characteristics identification procedure |

8.3.3.3

|

|

40

|

Evaluation of suppliers procedure |

8.4

|

|

41

|

Purchase procedure |

8.4.2

|

|

42

|

Supplier development & management procedure |

8.4.2.4

|

|

43

|

Outsourcing & procurement management procedure |

8.4

|

|

44

|

Evaluation of compliance procedure with statutory and other requirements of purchased products and services |

8.4

|

|

45

|

Control plan |

8.5.1

|

|

46

|

Production processes control procedure |

8.5.1

|

|

47

|

Production stages control procedure |

8.5.1.2

|

|

48

|

Production set-up verification procedure |

8.5.1.3

|

|

49

|

Total productivity maintenance system management procedure |

8.5.1.5

|

|

50

|

Production management procedure |

8.5.1.7

|

|

51

|

Special production processes validation procedure |

8.5.1

|

|

52

|

Product identification & traceability procedure |

8.5.2

|

|

53

|

Property of customers or providers management procedure |

8.5.3

|

|

54

|

Input & output management procedure |

8.5.4

|

|

55

|

Customer satisfaction measuring & monitoring procedure |

9.1.2

|

|

56

|

After sale service procedure |

8.5.5

|

|

57

|

4M Change control procedure |

8.5.6

|

|

58

|

First product control procedure |

8.6

|

|

59

|

Last finish product test procedure |

8.6

|

|

60

|

Raw materials test procedure |

8.6.4

|

|

61

|

Nonconformity control procedure |

8.7

|

|

62

|

Control of suspect products procedure |

8.7.1.3

|

|

63

|

Control of re-working the products procedure |

8.7.1.4

|

|

64

|

Product repair control procedure |

8.7.1.5

|

|

65

|

Data statistic & analysis procedure |

9.1.3

|

|

66

|

Internal audit procedure |

9.2

|

|

67

|

Management review procedure |

9.3

|

|

68

|

Corrective action procedure |

10.2

|

|

69

|

Problem solving procedure |

10.2.3

|

|

70

|

Error-proofing methodologies determination procedure |

10.2.4

|

|

71

|

Continual improvement procedure |

10.3.1

|

|

72

|

Work instructions |

8.5.1

|

|

73

|

Other documents |

—

|

Tiếng Việt

Tiếng Việt